Building a Reflow Oven With Controleo2

This page has been updated for the last time. It is no longer maintained. Please refer to the Controleo3 Build Guide for our latest build techniques. For more information about Controleo2, please refer to our FAQ on Controleo2.

This guide will show you how to build a great toaster reflow oven. It isn't

difficult to build your own oven, and the result can be equal or better than commercially available ovens.

Building it yourself will give you a better indication of what to look for, how it works and how to tune it to get

excellent results.

The reflow oven build described here is fully capable of fine pitch lead-free soldering

at very high temperatures, and can do it consistently and reliably. The entire tray can be filled with PCB's,

and all will reflow perfectly. It uses ControLeo2, a 4-relay programmable reflow oven controller.

This oven

is designed to reflow lead-free solder paste with liquidus temperature around 217°C (max temp around 250°C). This

is what is typically used by contract manufacturers making commercial PCB's. Typically, prototyping

conditions should mimic the production environment to avoid mass-produced surprises. If you use solder paste with

a lower liquidus temperature - some go as low as 138°C - you can get away with a lesser oven.

Choosing an oven to convert to a reflow oven

This guide assumes access to a 110VAC 15A outlet. You may have access to a higher voltage or amperage outlet, in which case you can choose a larger oven with a higher power output. To avoid tripping the fuse, we'll consider 1500W as the total allowable power draw. Here are the parameters in choosing the oven used in this guide:

- Small - A smaller oven means less metal to heat up. Smaller is definitely better!

- Power - Choose an oven that is powerful, but won't trip the fuse or overload the wiring.

- Elements - You need some elements on the top and some on the bottom to control where the heat comes from. Avoid resistive heating elements if possible because of their large thermal inertia. The more elements the better because good coverage helps to reduce hot and cold spots.

- Convection fan - This is definitely nice to have but isn't necessary. If you choose an oven with convection fan make sure there is enough space to mount the relays within the oven!

For this guide we found a suitable oven on Amazon.com. It was a brand new Black & Decker T01303SB toaster oven for just $30 shipped! Black & Decker sells many ovens with the same chassis, but with different controls, color or handle design so your oven may not look exactly like this one. It doesn't have a convection fan and the power consumption is 1150W. The "low" power consumption means we can add an additional heating element without blowing fuses. There are 2 heating elements - 600W on top and 550W on the bottom. The area for PCB's is 8"x10.5" (200mm x 260mm). Perfect!

Build overview for other oven types

The oven in this guide may be unavailable in your area, or you may want to use a different oven - perhaps with a convection fan. A convection fan is nice to have but most convection ovens are larger, cost more and are more difficult to modify. The conductive properties of aluminum in the PCB tray and insulation (Boom Mat) is more effective at eliminating temperature differentials than moving air. The Black & Decker oven used in this guide is 10 liters and runs off 110V.

Tips for Europeans (and other 240V countries):

- Look at the forum discussion here.

- Do not try to run a 110V oven through a 110V/240V converter! The power requirements are huge, as are the conversion losses. Use an oven designed to run on 240V.

- Some 240V ovens use two 120V elements wired in series. This is fine if there are 2 bottom elements in series, or 2 top elements in series - but if you only have one element at the top and one at the bottom then they must be 240V elements. If the oven supports "top heating" and "bottom heating" then most likely they are 240V elements (good).

- Do not connect 120V elements to a 240V supply! P = V2/R so wiring them this way will consume 4 times the power and likely burn out or melt the heating element.

Consideration is given to the current draw of the oven. In USA, most circuits can

handle 15 Amps so the maximum draw is 15A x 110V

= 1650 Watts. For a continuous load this value should be derated by 20%.

ControLeo2 can control 4 relays.

In this guide the 4 outputs are bottom element, top element, boost element and unused.

Example

1: Non-convection oven with 2 heating elements totaling 1150W

This describes the oven used

in this guide. Use a 350W boost element. This keeps the total power consumption a safe 10% below the 1650W maximum

so all elements can be on at the same time for a short period.

Example 2: Convection oven

with 4 heating elements totaling 1500W

An oven like this one has 4 elements. The bottom elements are both

300W and the top are 450W. It is slightly larger than the oven used in this guide.

- Do not underestimate the effects of thermal mass! Larger oven are considerably more difficult to heat up. Consider buying two of the same oven, and using one to donate heating elements to the other. Make sure this will still work with your electric circuit.

- A boost element should be added, but doing this will put the power draw beyond what a 15A circuit can provide. You may have access to a 20A circuit - great! If you don't add a boost element you'll need to go overboard with insulation. In addition to insulating the inside of the oven (Reflect-A-Gold and Boom Mat) you should also add some ceramic blanket insulation between the oven chamber and the outer shell.

- The highest wattage elements are on the top - not good. It is best to remove all the elements, install the insulation and then replace them, with the highest wattage elements at the bottom. Best to cut the wires and splice them back together using a butt connector.

- Use SSRs for the heating elements. The convection fan could be wired to be on all the time, or you can use a mechanical relay or small SSR to control it.

- Add insulation (like ceramic fiber blanket) between the oven chamber and outer shell. This is a big oven, and you need all the help you can get to ensure uniform temperatures that can follow reflow profiles.

- For the PCB tray, you can use a thin aluminum or copper tray resting on the wire rack. Remove as much of the cross-members as you can to reduce thermal mass.

- If you end up with an oven that is under-powered or under-insulated, consider using solder paste with a lower liquidus temperature (around 138°C) like Chip Quick SMDLTLFP10.

If you are considering using a convection oven, then blog 1 and blog 2 may help you.

Is a boost heating element necessary?

Common problems in home-made reflow ovens (or cheap commercial ovens) are hot and cold

areas. A cold spot is an area that doesn't get enough heat to activate the flux at the right time, and allow

the solder to reach liquidous temperature and reflow. A hot spots is an area that get too much heat and results in

warped or blistered boards. Components can discolor, but some of the worst damage is what you can't see; the

mean-time-before-failure (MTBF) of burnt IC's can be severely compromised.

How does the boost element help?

- Heat comes from an additional location, helping to distribute the heat around the oven.

- All elements can be run cooler, so that it isn't an intensely concentrated heat source.

- It is installed at the bottom of the oven, keeping heat away from sensitive components.

Is insulation necessary?

Good insulation is absolutely necessary when building your own reflow oven. It is

almost impossible to have too much insulation. If you're using leaded solder paste and only reflowing a

single small PCB at a time then it is possible without insulation. However, the goal in building this oven is to

be able to use the entire oven tray for PCB's using high-temperature lead-free paste. Quality insulation

capable of withstanding high temperatures is expensive but worth it. We recommend using Reflect-A-Gold, Floor &

Tunnel Shield II and ceramic fiber

blanket.

In this guide, Reflect-A-Gold and Floor & Tunnel Shield II are used inside the oven

to prevent heat loss to the steel oven walls. Ceramic fiber blanket insulation is added to the outside of the oven

chamber (and inside the outer shell) to further reduce heat loss. We also use a high-temperature silicone glue to

seal the air gaps between the oven panels and Nomex high-temperature gasket to reduce the air gap around the oven

door.

Quality insulation is not cheap

There is fake Reflect-A-Gold available on the

Internet. It looks the like the real deal, and our testing shows the insulating properties to be very similar.

However, the adhesive on this tape doesn't stand up to the high reflow temperatures as can be seen here and here. Some

insulation (we're looking at you, Heatshield Products) rated to higher temperatures than Reflect-A-Gold don't work as well.

How does insulation help?

- It reduces the thermal mass of the oven, because less heat gets absorbed by the steel walls.

- By reflecting or conducting heat, it helps to eliminate hot and cold spots in the oven.

- Good insulation means less energy is needed to reach high temperatures. This means the heating elements can run cooler, further helping to even out temperatures in the oven. For this particular oven, the bottom element runs at a 95% duty cycle without insulation, but just 60% when insulated.

Use insulation and use a lot of it! Once you see the great results you get you'll increase the number and complexity of the boards you design. Do it once, and do it right.

Thermocouples

One is good, more is unnecessary. If the desire is to get an average reading you can

connect multiple thermocouples in parallel. Thermocouples generate a micro-voltage that is read by the MAX31855

IC, so wiring them in parallel will give you that average. If the desire is to measure temperature variance around

the oven, the best method is to use Temperature Test Labels, as shown here. This will give you a

more accurate picture of the variance and let you know where the hot and cold areas are in the

oven.

Non-convection ovens are inherently left-right temperature balanced. Top-bottom imbalance is expected

(and desired). Front-back imbalance will occur because of the wattage and location of the heating elements, type

of insulation and the oven door. A convection fan may reduce front-back variation but will also introduce some

amount of left-right fluctuation. In almost all ovens, the center will be hotter than the corners.

Step 1: Open it up

Disclaimer: Converting an

oven to a reflow oven will probably invalidate the manufacturer's warranty on the oven. Ovens use high

voltage electricity and potentially lethal electric currents. Whizoo (and Peter Easton) cannot be held liable or

responsible or will accept any type of liability in any event, in case of injury or even death by building and/or

using or misuse of this information posted on this web site. By accessing, reading, and/or printing the articles

presented here you agree to be solely responsible as stated in the above disclaimer and exempt Whizoo and/or Peter

Easton and/or Mitchell Herbert from any criminal and/or liability suit. Safety is a primary concern when working

with high voltage circuits and high-temperature ovens. Play it safe!

Tip:

click on any photo to see the high-resolution version.

Tip: think about ordering an aluminum tray if

you haven't already done so. One tray is included in the build kit.

This should be pretty

easy. Make sure the oven is UNPLUGGED and keep track of where all the screws go.

Tip: now is a good time to identify sharp edges in and around the oven. Place tape over them so you don't cut your hands as you work on the oven. Or don't - because the best projects are the ones that involve blood.

Step 2: Remove the old controller

To keep things safe and to make space for the new controls you should remove all unnecessary parts from the oven. Identify the wiring used by the elements; you'll need to connect them to the SSR's in step 12. When cutting wires, leave them as long as possible; they need to be able to reach your SSR's. Save any wire from the oven. It is high-temperature wire that could come in handy later. The top control is removed because that is where the wires to the controller will be fed through.

Step 3: Mount the relays

ControLeo2 supports both mechanical and solid-state relays (SSR). If you don't

plan to use your oven much, or if you don't have 2 pennies to rub together you can use mechanical relays. The

contacts in mechanical relays do wear out over time. SSR's have no moving parts so they aren't affected

by physical shock, vibration or changes in altitude. They operate silently and produce little electrical

interference. They don't produce any arc so they are suitable for hazardous environments. We only use

SSR's when building reflow ovens.

When choosing SSR's keep in mind the environment they will

operate in (it is hot and the heat sink is relatively small). You should derate the SSR to allow for this. In the

case of an SSR controlling power to two 375W elements, the current will be 2 * 375W / 110V = 7 Amps. Choose a 20A

SSR to be safe.

The relays are mounted to a thermally conductive piece of metal. Copper has excellent

thermal properties, and aluminum is pretty good too. That's why these metals are used as heat sinks and

inside computers. Steel is actually not that good. Each SSR can handle 5A without needing a heat sink, and these are getting

less than 7A each. When doing a reflow, the SSR's and aluminum plate get slightly warm.

The SSR's

in this guide are mounted on a 6" x 6" aluminum sheet that is 1/16" thick. Figure out how this

sheet will be mounted in the oven, and how the relays will be mounted on the sheet. Keep the sheet away from the

oven wall, and as low as possible (heat rises). Place a thermally conductive pad or paste between the SSR's

and the aluminum sheet. Rivets are great for keeping things together but you can use nuts and bolts too. Make sure

nothing can come loose because the last thing you need is anything rolling around near high-voltage

wiring!

Tip: make sure all the oven wires will be able reach the

SSR's.

Tip: remove burrs on any holes wires will be fed through. A countersink bit is good for

this.

Tip: (convection ovens) if the aluminum sheet is smaller than used here, or the relays are

carrying more current then consider adding active (cooling fan) and passive (heat sink) cooling to ensure

the SSR's don't overheat.

Step 4: Prepare the enclosure

Figure out where ControLeo2 will be mounted. Make sure the oven door can still open

(don't forget about the servo bracket), and the oven can be put back together! Drill a hole through the ABS

plastic enclosure of sufficient size for the wiring. ControLeo2 has a USB port that is used for firmware upgrades

and temperature logging. Getting to this USB port once everything is assembled is very difficult and you run the

risk of bending wires past their breaking point. It might make sense to make a hole for the USB port too - just

enlarge the pilot hole behind the sticker.

Tip: having access to the USB

port is necessary to update the firmware or logging temperatures to a PC. The hole doesn't look bad

with a piece of black electrical tape over it. It is a very good idea to make the hole, and then square it

off so that it easily accepts a USB cable.

Step 5: Drill holes

The boost element will be held up by 3/16" x 1-1/2" eye bolts. The ends of

the element don't get nearly as hot as the middle, so they eye bolts should be located near the ends of the

element.

You'll be making 12 holes in this stage:

- A hole for the wires from the boost element into the control chamber (3/16").

- A hole for the wires from the thermocouple probe into the control chamber (3/16").

- 2 holes for the eye bolts used to support the boost element (3/16").

- 2 holes for the zip tie that will hold the power supply (5/32").

- 2 holes to hold the SSR plate in place (9/64").

- 4 mounting holes for the enclosure (1/8" and 1/16").

Firmly attach the SSR plate to the oven. Avoid using the wall to the oven as a mount

point. Take care to ensure no metal filings are left behind! When you're done, make sure the wires for the

thermocouple and the boost element fit through their respective holes

Tip: use a

countersink bit to deburr the holes that wires go through!

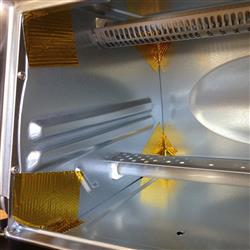

Step 6: Insulate the oven

Warning: this is probably the most difficult part of

the build!

For the most part, the oven is insulated using a 2" x 18' roll of

Reflect-A-Gold. This insulation is capable of handling continual temperatures up to 450°C (850°F). The goal of

this insulation is to close the air gaps where heat escapes and to reduce the thermal mass of the oven by reducing

the amount of heat lost to the steel chassis. If you have it, you can use high-temperature silicone glue to block

the air gaps.

Make sure to use genuine Reflect-A-Gold, not some fake stuff available from eBay or

AliExpress. The insulating properties are very similar but the adhesive on this tape doesn't stand up to the

high reflow temperatures as can be seen here and here.

Boom

Mat is used below the bottom element. This insulation can handle continual temperatures up to 950°C

(1750°F). The bottom elements are on most of the time, and the aluminum helps to wick away the heat from the

center of the oven and spread it evenly about the bottom. It is tempting to put Boom Mat above the top element

too. Unfortunately the adhesive will fail at high temperatures and the Boom Mat will fall onto the top element and

catch fire. Yes, this is what happens!

Given the cost of the insulation, we focus on areas where the

greatest benefit is obtained. Look for seams where hot air can escape. The top of the oven, the door, the wall to

the control chamber and the area around the heating elements are the most important areas to cover. A peep hole in

the door allows you to monitor the progress of the reflow.

Tip: use a

bungee (elasticated cord) to hold the oven door open while you place the insulation.

Keep a small piece of Reflect-A-Gold to insulate the around around the thermocouple (next step). To place the Boom Mat, peel away the plastic backing on the far edge and place it in the oven. When you're happy with the location, press the exposed edge down and remove the rest of the backing.

Tip: you can use Nomex high-temperature gasket to reduce the air gap around the oven door.

Step 7: Install the boost element

The boost element is a 110V 350W resistive heating element normally used for heating

molds. The boost element must fit tightly inside the eye bolt. It may be necessary to enlarge or reduce the size

of the eye hole. Drill through the Boom Mat using the holes you made in the oven earlier as a guide. Put the

element through the eye bolts and then put the bolts through the holes. Wrap some Reflect-A-Gold around the wires

where they go through the oven wall to protect them. Make sure everything is bolted down securely.

Tip: having only one eye bolt fit tightly on the boost element makes

installation easier.

Step 8: Install the thermocouple

The "k-type" thermocouple probe is fiberglass insulated and can measure up to

550°C. This particular probe is used because it has low-mass tip so it responds very quickly to changes in

temperature. The thermocouple should measure the temperature experienced by the solder so the best way to mount

the thermocouple is to use aluminum tape and tape it to the board being reflowed. This is a really good method in

theory, but in practice it falls short. It is difficult to place the probe on the PCB (even a sacrificial PCB) and

get consistent results. The thermocouple could be over a via, or there may be a tiny air gap between it and the

PCB. There's also the ever-present danger of bumping components when trying to place the

thermocouple.

A better method is to recognize that the thermal mass of the oven is largely unchanged

between runs. It is best to place the thermocouple in a location that should reflect the board temperature and is

away from any direct heat from the heating elements. We have built ovens and reflowed boards using both placement

methods and we recommend this method without reservation.

Make sure the thermocouple probe is securely

mounted and the hole to the control chamber is sealed.

Step 9: Install the power supply

We've decided to mount the 5V power supply for ControLeo2 inside the oven. Add

wires (not supplied) to the power supply to make it easier to connect once inside the oven. Cut the end off the

power cord and identify the positive and negative wires using a multimeter. Resist the temptation to tin the wires

- this is not recommended. You can use ferrules if you like.

The control chamber (with the

relays and power supply) gets warm during a reflow - but nowhere near hot enough to melt wire insulation. While

you must use high-temperature wire inside the oven and for any wires touching the oven walls, ordinary wire can be

used as shown in the photos.

Tip: after exposing the wires in the power

supply, it is an excellent idea to connect it to ControLeo2 to make sure things work. Adjust the LCD

contrast if necessary. Power from the USB port goes through a diode, so the LCD contrast will differ between

USB power and the 5V power supply connected using the screw terminals.

Tip: now might be a good time

to

update the firmware running on

ControLeo2. The latest version is v2.0.

Tip: now is a good time to put button covers (colored plastic

spacers) on ControLeo2. This is shown in step 16, but doing it now is easier.

Tip: instead of

soldering wires onto the power supply prongs, you can use female spade crimp

connectors.

Attach the enclosure to the oven now.

Step 10: Do the high-voltage wiring

It is important to get your high-voltage wiring right! If your oven is 220V your

elements may be wired in series, not parallel. If you are not 100% confident dealing with electricity, please

consult an electrician. You can also ask questions using the feedback form below.

The "hot" wire

goes to each of the SSR's and to the 5V power supply. The "neutral" wire goes to one end of each

heating element and also goes to the 5V power supply. The other end of each element is also wired to a SSR. Use

zip ties to keep the wiring neat.

Tip: label the SSR's so that you

know which SSR controls which heating element.

Step 11: Feed the wires out of the oven

The wires coming from the oven are:

- Wire from the 5V power supply.

- Wire for 3 SSR's. The relays have common positive, so we use a 4-conductor wire for 3 SSR's. The wire needed won't be carrying much current (max 10ma @ 5V per SSR) so even something as thin as a USB cable can be used. Mechanical relays need around 50ma @ 5V each, so again the wire doesn't need to be a heavy gauge.

- The thermocouple wires.

Feed the wires through the grommet and through the braided sleeving. To keep things neat and secure, we use 10" of 1/4" braided sleeving.

Step 12: Mount the door servo

The servo is mounted without the rubber insulators; they really aren't needed here. Feed the servo wire, and the oven wires through the enclosure. Add a zip tie for strain relief - but first make sure that you have enough length in the wires to reach the screw terminals on ControLeo2!

Step 13: Add servo hardware to ControLeo2

Get out your soldering iron! Some components have to be soldered to the board to support the servo

- A 3-pin header is soldered to GND, 5V and D3.

- Most servos will make a sudden sharp movement when you first apply power. A 10K pull-up resistor will stop that behavior. The resistor is placed between 5V and D3.

- When the servo moves, the stall current can lower the voltage going to the board and cause a brown-out condition. The 220uF capacitor is needed to prevent this. Connect it between 5V and GND. Yes, just like the photo shows. No, it isn't connected to 3.3V. Yes, we know it looks like it is - but it isn't.

Tip: the capacitor is polarized, so make sure you solder the negative side to GND!

Step 14: Wire up ControLeo2

There is a definite order to attaching the wires to ControLeo2. Avoid repeatedly

bending wires past their breaking point. At each step a test can be performed to ensure correct

operation.

Attach the spacers to the board. You can use tape so the spacers stay on the screws - or just

use pliers and squeeze the middle of the spacer before placing the spacer on the screw. Strip all the wires so

that they are ready to be inserted into the screw terminals. Unscrew the screws in the screw terminals.

Attach the 5V power wires.

Test 1 - check 5V power

Make sure

your high-voltage wiring is safe, then plug in the oven. ControLeo2 should receive power and start up. If you

didn't do this in step 9, this is a good time to adjust the contrast on the LCD display.

>>> Unplug the oven when you're done.

<<<<

Attach the thermocouple wires. Green is "-" and red

is "+". If you're color-blind just guess! No harm will occur if the thermocouple leads are

reversed.

Test 2 - Check thermocouple operation

Make sure your high-voltage wiring is

safe, then plug in the oven. ControLeo2 should receive power and display the temperature. Open the oven door and

hold the tip of the thermocouple. The temperature should increase - unless you have icy hands. If the direction of

temperature change isn't correct then reverse the red and green wires.

>>> Unplug the oven when you're done. <<<<

Connect the servo and the low-voltage SSR wires.

- D4 = black (bottom element)

- D5 = green (top element)

- "+" = red (common positive)

- D6 = white (boost element)

- D7 = unused

Screw ControLeo2 into the enclosure (don't put the cover on yet in case you need

to access the wiring again). Feed the braided sleeving into the control chamber.

Tip: you might want to take a photo of your wiring, in case you need to refer

back to it.

Step 15: Finish the low-voltage wiring

Keep the low-voltage wiring as far as possible from the high-voltage wires. Take

special care of the thermocouple wire; it is carrying millivolts and close proximity to wires carrying large loads

can interfere with temperature readings.

The wires are connected as follows:

- red - connected to all 3 SSR's.

- white - connected to the boost SSR.

- black - connected to the bottom SSR.

- green - connected to the top SSR.

Test 3 - Check SSR operation

Make sure your high-voltage wiring

is safe, then plug in the oven. ControLeo2 should receive power and show a test menu. You can watch this short video to see how the menu system

works. Pressing the bottom button will cycle through each SSR. Watch the SSR and make sure the LED on it lights up

at the right time. Expect to hear some buzzing from the elements as they start to heat up.

>>> Unplug the oven when you're done.

<<<<

Step 16: Close the oven

Remove the plastic film protecting the LCD display. Put colored spacers on the buttons

- this gives them a nice look and feel! Put the cover on the enclosure and close up the oven.

Tip: before closing the oven make a last check for loose nuts, bolts, screws,

wires and metal shavings. Use zip ties to keep wires in place. Make sure the chassis screws you're

about to insert don't pierce any work you've just done.

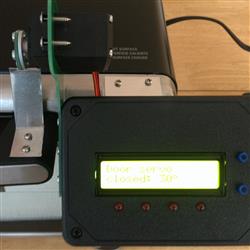

Step 17: Finish the door servo

Turn on the oven, and navigate through the menu to the door open position. It should show 90° - this is the mid-point in the servo movement. If it doesn't show 90° then press the top button until it does. Attach the servo arm to the servo disc using four M3 screws. Mount the arm to the servo in what you think will be the mid-point of it's movement.

Take a 3" x 1/2" piece of aluminum and drill 2 holes in it using a 1/8"

drill bit. Give it a 90° bend as shown in the photos. Drill 2 pilot holes in the oven handle using a small

1/16" or 5/64" drill bit. Attach the aluminum to the handle. Once you've done this, use

ControLeo2's menu to adjust the open and closed positions for the servo. The oven door should open around

1". That is enough to provide sufficient cooling after the reflow.

The door servo is always moved to

the closed position when the oven powers up. The door will be opened slowly soon after the maximum temperature is

reached, and closed again when the oven cools to 50°C.

Step 18: Install the PCB tray

The PCB tray is the single most important part of a reflow oven. Good heat distribution

is paramount to a successful reflow and the tray the most important part of the equation. The trays that typically

come with ovens are made from steel (if it is magnetic it is steel), which you already know is not good. Using the

rack is like going to the beach wearing a bikini and expecting a "no-lines" tan!

For this oven

we're using a custom cut 1/32" thick 8"x10-5/8" sheet of 5052 aluminum. 1/32" is the right thickness; any

thicker and we're just adding thermal mass and any thinner it will lose rigidity. Any metal with a good

thermal conductivity will work.

Another good approach - especially for convection ovens - is to use the

rack that came with the oven but remove most of the wires to reduce thermal mass. A thin aluminum or copper sheet

can be placed directly on top of this modified rack. Convection ovens will need good airflow around the metal

sheet, so make holes around the edges if necessary.

Step 19: Configure ControLeo2

Navigate to the Reflow Wizard setup menu. You can watch this short video to see how the menu system

works.

Configure the outputs D4, D5, D6 and D7 as you've wired them. You can also set the maximum

temperature. The default maximum temperature of 240°C is good for lead-free reflow. If you are using leaded solder

then change this to the value recommended by your solder paste datasheet. Pressing the top button repeatedly will

increase the temperature up to 280°C, and then it rolls around to 175°C. The reflow curve is automatically

adjusted based on the maximum temperature.

Step 20: Let the Reflow Wizard learn your oven

Tip: if you haven't already, now might be a good

time to

update the firmware running on

ControLeo2. The latest firmware is v2.0.

This step is going to take some time. If you've

built your oven exactly as described above it could take 1 cycle to verify that your oven conforms to the

J-STD-020 standard, but the odds are it will take a few cycles (perhaps 10) to get out of "learning"

mode.

Tip: the tray MUST be in the oven during learning mode! The thermal

mass must as close to normal reflows as possible.

- You want to run this test outside, or in a well ventilated area. There will be some fumes - this is normal.

- Place the PCB tray in the oven, but don't place any boards on it.

- Close the oven door.

- Start a reflow. The LCD screen will tell you that learning mode is enabled.

- If the temperature rise is too fast or too slow, the learning run will be aborted. A message will be displayed on the LCD screen to this effect.

- The Reflow Wizard will make some adjustments to its settings. Those settings are stored in non-volatile RAM (EEPROM).

- Open the oven door and let the oven cool to room temperature.

- Seriously, let it cool down. Wait 20 to 30 minutes.

- Go back to step #3.

Once the temperature rise meets J-STD-020 the Reflow Wizard will leave learning mode.

From this point on the Reflow Wizard will continuously monitor every reflow and will make very small adjustments

if needed.

If one of the outputs is reconfigured (for example, if D4 is changed from "Bottom" to

"Top") or the maximum temperature is changed by more than 5°C then the Reflow Wizard will re-enter

learning mode.

If you want to monitor the Reflow Wizard's performance, you can install the Arduino software on your PC and monitor the status messages

using the Arduino Serial Monitor.

If you want to understand how the Reflow Wizard works, you can look at

the source code here.

Insight into the solder paste reflow curve

Solder paste

manufacturers try to sell paste to contract manufacturers with conveyor belt reflow ovens. Time is money for them,

so the reflow graph typically shows the shortest reflow duration under ideal conditions. All datasheets state

something along the lines of "use this graph as a starting point for process optimization". Another

point to keep in mind is that your oven doesn't get instanly hot when you turn it on, so it is best to

zero-base profile graphs to 75°C for a better comparison. Taking a longer time at lower (pre-soak) temperatures is

almost inconsequential to the process.

Step 21: Run some test cycles

Use scrap PCB's and components you no longer need. Place some solder paste on the

boards and some components. A simple test is the "yellow capacitor" test as documented in a Kickstarter

update. A better method is to use Temperature Test Labels, as shown here.

Place boards in

a 3x3 grid on the oven tray. This will help you determine if you have any hot or cold spots in your oven. The

corners typically run a little cooler and the center a bit hotter. Do a reflow and examine each board in turn. Was

there sufficient heat for the solder reflow to happen, but not too much that the boards warped or components were

burned?

If needed, the maximum temperature setting can be adjusted up or down depending on your results.

Keep in mind that the error in the MAX31855 is 2°C and the thermocouple probe is around 3°C.

If not using

the door servo, when instructed to open the oven door open it an inch or two. Be careful not to let the cool down

rate exceed 6°C/second; the optimal rate is 2°C/second. Once the oven cools to 100°C the boards can be removed,

but you can leave them in longer so you don't need gloves to handle them. The oven must be below 50°C to be

able to start a reflow.

Step 22: Final thoughts

Reflow process

There are a number of guides on how to do this, and a quick search of YouTube or the Internet will produce results.

Boards and paste

OSHPark produces excellent quality boards and delivers them

quickly. For most prototype boards, having a stencil reduces assembly time and improves soldering so much less

rework is needed. We love stainless steel stencils, and often order boards and stencils from Smart Prototyping in China. Their quality is not as

good (around 1 in 250 boards has a problem) but overall we're very happy to recommend them.

We

personally use Chip Quik SAC305 lead-free paste and we're happy with the results. From feedback we've

received, any no-clean lead-free paste appears to be as good as any other. Paste freshness is important; the flux

in the paste will degrade over time. Keep it refridgerated per the manufacturer's instructions. Fine-pitch

components and especially BGA's will need the freshest and best quality paste. If you're doing a

low-frequency design with large component pads you can probably use cheaper, older paste.

Double-sided boards

ControLeo2 is not well designed to handle two different solder pastes, with their different reflow profiles. However, there are techniques to make this work:

- Use epoxy to hold the larger components on the 1st side in place. Surface tension will keep the smaller ones in place when reflowing the 2nd side.

- Reflow the more complex side of the board and hand-solder the 2nd side.

- Some users save the learnt settings for each type of paste, then reflash ControLeo2 before each reflow. This is cumbersome though.

The source code for ControLeo2 is open-source, so if you'd like to improve this we'd love to share your efforts

with our users!

You're done! Enjoy your new reflow oven.